SEM Advancing Research

November 12, 2020

The Bureau of Economic Geology has long been at the forefront in applying scanning electron microscope (SEM) technology to create detailed characterization of rocks.

The FEI Nova NanoSEM scope in its Scanning Electron Microscopy Laboratory is enabling groundbreaking discoveries at the nano scale by combining its own advanced scanning capacity with other analytical methods and cutting-edge sample preparation.

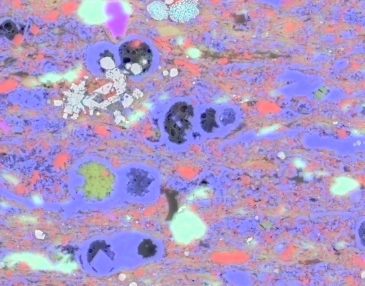

Researchers at the laboratory are combining the scope’s highresolution field emission with energydispersive X-ray spectroscopy and cathodoluminescence methodologies to gain valuable new insights into depositional environments, diagenesis, fracture systems, and the geological conditions, processes and resource distribution in hydrocarbon reservoirs.

This technique is aided by a process known as element mapping, which makes it possible to see where rock pores are in relation to the mineral phases of shales. This characteristic varies in different rocks, allowing scientists to use pore location to infer information about the various stages of maturation in different rock types.

Recent research demonstrated the benefit of this method in identifying magnesium in shale samples. X-ray fluorescence interpretations alone could not distinguish whether the mineral hosting the magnesium in the sample was chlorite or dolomite. But when false color was assigned to magnesium and added to an SEM image of a sample, the mineral hosting the magnesium could be easily seen and identified. This interpretation method has significant implications at a variety of scales, from microfractures, to fluid-flow studies, to reservoir characterization.

A sample preparation technique used by the lab is also helping shale studies by illuminating rock characteristics that are imperceptible using traditional SEM technologies. Argon milling creates a clean and smooth sample by shaving an extremely thin layer of material off the sample, with the resulting image revealing shale pore structures in amazing clarity.

Back to the Newsletter