Striking It Big With Nanotech

October 22, 2014

Jackson School researchers are unlocking the mighty impacts of tiny technology for energy development and recovery

By Joshua Zaffos

The difference between boom and bust in the field of energy development is often a matter of inches and guesswork: An abundant reserve can be tapped—or overlooked—depending on the location of a well and properties of a reservoir.

While advances in drilling and mapping in the 21st century have eliminated much of the old-school wildcatters’ speculation, researchers and engineers are still constantly working to improve practices and recovery rates of oil and gas drilling, including hydraulic fracturing. At the Bureau of Economic Geology (BEG) within the Jackson School of Geosciences, scientists are taking a page from medical science trailblazers by using nanotechnology—molecular-scale engineering—to make huge gains with tiny tools.

“Nanotechnology within geology and the oil and gas industry hasn’t really been mainstream,” said Scott Tinker, director of the BEG and the Advanced Energy Consortium (AEC). “This is cutting-edge research going on at the Jackson School. It’s new thinking.”

“We saw that, within the medical industry, they were coming up with these nanoparticles that you could put in a human body to actually search out cancer cells, and then do some things with those particles to eradicate the tumors,” Tinker continued. “We were so fascinated and we said, ‘Why can’t we do something similar with the earth’s body?’ ”

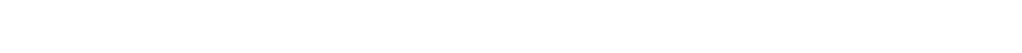

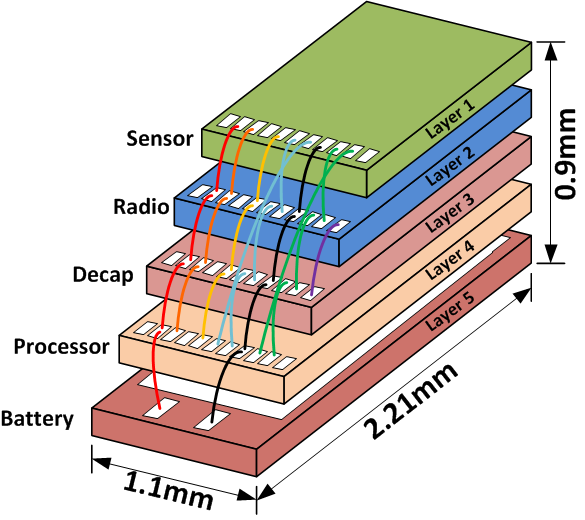

Specifically, Jay Kipper, associate director at the BEG and AEC, and others are testing how industry can deploy millions of particles of “smart dust” sensors and micro-scale tools down into wells in order to gain a better picture of underground formations and their characteristics.

Nanoparticles are so small that roughly 800 to 8,000 of them would fit across the diameter of a human hair. The miniscule size and relatively large surface-area-to-volume ratio means the particles follow quantum mechanics rather than the standard rules of physics, so they may have enhanced reactivity and mobility traits, for instance. That means scientists can potentially send nano- and micro-scale sensors into wellbores and inter-well space to collect data for a number of parameters, such as temperature, pressure and other chemical and physical properties. The clearer picture underground can guide improved oil and gas recovery and minimize environmental impacts.

“It’s so difficult for a geologist to know what’s really going on in a reservoir,” Kipper said. “There’s a lot of interpretation, but with more data we will be able to make smarter and more accurate predictions.”

Team Effort

Bureau researchers embarked on their big plans with nanotech in 2008, launching the AEC. Tinker and Kipper reached out to scientists from academic institutions around the world and leaders in the energy industry. The consortium has funded researchers from the Jackson School, Harvard, Caltech and 30 other universities from around the world and has been supported by Shell, BP, Schlumberger and many other major energy corporations—“the best and the brightest” among geosciences and nanotechnology, Kipper said.

By bringing together academics and industry, the consortium is facilitating cooperative research in nanotechnology and leveraging the partners’ expertise—and investments—ahead of any market competition.

“By design, this is run very different than a typical university research program,” Kipper said, noting that the group meets every two months. “We’re not doing just the same old traditional research. We’re introducing innovation to the field.”

That innovation has focused on a few key initiatives and research areas. Researchers are developing sensors that range in size from nanometers (1 nanometer equals a billionth of a meter) to a millimeter cubed. These devices can be sent underground and withstand the conditions to transmit data that helps characterize a reservoir’s geological, chemical and physical details. Consortium partners and project managers are also studying how they can use nanotechnology as high-powered contrast agents to boost visibility underground and improve existing drilling tools and techniques.

Mohsen Ahmadian, an AEC researcher and project manager who previously worked in the semiconductor and biotechnology industries, said millions of electromagnetic nanoparticles can be co-injected into wells during typical water-flooding processes and serve as “in situ tracers” to help “illuminate” subsurface reservoir fluid paths that geologists might otherwise never find. He compares the approach to a “large-scale MRI” for oil and gas reserves.

“The enhanced recovery of oil is very similar to targeting a specific disease in human beings,” Ahmadian said. Every reservoir has specific characteristics, he added, and “fingerprinting” a reservoir, as with a disease, would enable targeted treatment.

Just as the medical industry has collaborated with other scientific disciplines to solve “big” problems, the energy sector will benefit from the advancements made in other fields through the consortium.

“I strongly believe the marriage of different industries and scientific disciplines can lead to much better ways of addressing some of the critical questions we have in the energy sector,” Ahmadian said. “This vision is being put into practice at the AEC.”

Nanotech’s Expanding Role

The geophysical applications and opportunities of nanotechnology have only grown with the recent seismic shift across the energy industry. When the AEC began, petroleum geologists were just beginning to pay attention to shale gas reservoirs. The rise of hydraulic fracturing and horizontal and diagonal drilling has opened these plays to increased exploration and development. Scientists are still learning about how these formations hold resources, move fluids and generally behave compared with larger-pore sand and carbonate reservoirs that have more traditionally been drilled.

As a result, companies using hydraulic fracturing typically only recover a small percentage of resources from the better parts of the shale gas reservoirs, meaning they leave a major share—and billions of dollars’ worth—of gas or oil underground due to economic and technological constraints and gaps in data. Studies with nanoparticles hold vast potential to fill in the blanks, where even a modest increase in recovery would have major impacts.

“If we can get a better set of data and more information to make interpretations, it’s going to translate into higher recovery,” Kipper said. “If it is 1 percent [increased recovery], it will translate into billions of dollars for the industry.”

For now, the work of the consortium and its members is progressing mostly in labs and through initial field tests. Kipper said commercial production of nanoparticles and sensors for the energy industry is a few years away, but researchers have been encouraged by results and haven’t run into any major roadblocks in their studies.

“We didn’t know much about subsurface nanosensing [when we started], but that’s where some of the best ideas come from, when you get a bunch of smart people together and challenge and fund them,” Tinker said. “We’re giving birth to a whole new scientific space and opening a new area for application of nanotechnology.”

Back to the Newsletter