Petra Nova: Producing Power and Trapping CO2 Underground

November 18, 2017

Deep underneath an old Texas oil field in Jackson County, science and economics have come together to achieve something unique.

For the first time in this country, a commercial-scale project is taking carbon dioxide emissions (CO2) from a coal-fired plant and storing them in rocks beneath the ground so they cannot escape into the atmosphere and impact the Earth’s climate.

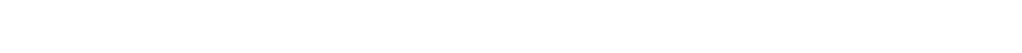

The project — Petra Nova — is removing CO2 from a unit of the W.A. Parish power plant near Houston and piping it some 80 miles to the southwest where it is pumped approximately a mile beneath the West Ranch oil field. The greenhouse gas is not only being trapped underground at the field, but is also being used to improve oil production through a technique known as enhanced oil recovery. It is a key aspect to making the $1 billion project economically viable by using the profit from the sale of oil to pay for the carbon capture system.

The job of monitoring the CO2 deep underground falls to the Bureau of Economic Geology, which is working with Texas Coastal Ventures, a partnership of Petra Nova and oil field operator Hilcorp Energy Co.

“We really need to have not only the expertise of the UT Bureau of Economic Geology, but the independence,” said Greg Kennedy, senior project director of asset management for NRG Energy, a

main partner in the Petra Nova project, and the project’s liaison to the bureau.“We need the University of Texas for an independent, high-quality assessment of that side of the project so we can actually determine that the captured CO2 is staying underground and not entering the outside environment.”

The idea of storing CO2 emissions is not new. The bureau’s Gulf Coast Carbon Center has been leading research on the issue for more than a decade, helping perfect the technology in a series of pilot projects around the country. Given the bureau’s long history with the technology and its focus on research that tackles tough problems that combine energy, the environment, and the economy, it was well-positioned to assist with the ground-breaking project, said bureau Director Scott W. Tinker.

“Petra Nova is a natural fit for us,” Tinker said. “The project is at the intersection of government, private industry, the environment and public policy. It’s an area I like to call the radical middle — an area where solutions to tough problems are found and things get done.”

Capturing Carbon

Although the project has been in the design phase for many years, Petra Nova started operating in December 2016, taking more than 90 percent of the CO2 from 240 megawatts of power production (enough power to serve about 200,000 homes) and piping it to the West Ranch oil field. Petra Nova is capturing more than 5,000 tons of CO2 per day, according to NRG Energy, which is equivalent to taking more than 350,000 cars off the road for a year.

The U.S. Department of Energy has been encouraging such projects for years through a series of programs and grants, but no commercial scale project had come to fruition in the U.S. before Petra Nova for a variety of reasons. First and foremost is the costs that carbon capture and storage add to power production. NRG Energy and partner JX Nippon Oil & Gas Exploration were able to make the $1 billion project economically viable by using the captured CO2 to increase oil production at the West Ranch field.

The project was also the beneficiary of a $190 million grant from the Department of Energy’s Clean Coal Power Initiative Program, which helped pay for the carbon capture unit. The resourceful approach earned the praise of Texas Gov. Greg Abbott.

“NRG and JX Nippon’s Petra Nova is the type of innovative, technologically advanced project that proves time and again that Texas is the world leader in energy innovation,” Abbott said in a prepared release. The enhanced oil recovery at West Ranch is expected to boost oil production from around 500 barrels per day to as much as 15,000 barrels per day, Kennedy said.

This technique involves pumping CO2 into the field, where it mixes with oil and helps release it from the rock formation so it can be pumped to the surface. The CO2 is removed from the oil above ground and then injected back into the ground where it is trapped. At that point it’s up to researchers from the bureau to monitor the CO2 to ensure it stays put.

They are accomplishing this through acombination of techniques that monitor deep subsurface pressure, groundwater, soil gas and other parameters that provide information on the status of the CO2 after it is stored underground.

Tracking Carbon

The monitoring project is being led by Susan Hovorka, a senior research scientist and principal investigator of the bureau’s Gulf Coast Carbon Center.

Hovorka and her colleagues carefully studied the subsurface environment under the field for more than a year to understand conditions before the project began.

One of the main issues, Hovorka said, is that pumping CO2 into the ground elevates pressure in the injection zone, which could theoretically lift fluids containing dissolved CO2 through damaged or flawed wells toward the surface. Once out of the ground, the greenhouse gas would escape into the atmosphere.

To ensure this doesn’t occur, Hilcorp Energy has inspected each existing well and brought all up to current standards so they do not exceed the original natural pressure of the oil field. As an extra precaution, researchers have installed pressure gauges in deep wells more than 3,000 feet below the surface.

These gauges act as an early warning system for potential CO2 leaks because they are above the zone where the CO2 is injected. Increases in pressure at this level would indicate that fluids may be leaking upward, giving the operator time to find and repair wells if needed. The extensive CO2 monitoring at Petra Nova is a precaution, Hovorka said. She stressed that she does not expect any leaks to come bubbling from below and that none have occurred to date.

Hovorka said that crews are also monitoring groundwater and soil gas for signs of CO2 leakage. To do so, scientists are watching parameters that would change during a spill or leak, specifically, the ratios of nitrogen, CO2, methane, strontium isotopes, carbon isotopes, light hydrocarbons and noble gasses. Hovorka described these parameters as “distinctive markers” of fluids from deep areas. They have a different chemical signature than fluids from shallower areas, a difference that makes for a good indicator to identify CO2 that leaked toward the surface from the deep subsurface.

“Stakeholders could be concerned about any one of a number of environmental changes, and without these markers it would be hard to say for sure if the change is because of fluid from the project or some other shift in the environment,” she said.

The Gulf Coast Carbon Center has developed these methods through

pilot projects across the country over the last decade. The big difference in Petra Nova, said Hovorka, is the full industrial scale.

“It is really exciting to take what you have been working on in R and D and take it to commercialization,” she said. Petra Nova is unique for now. But the project was designed with replication in mind, using commercially available technology.

The carbon capture system was jointly developed by Mitsubishi Heavy Industries Ltd. and the Kansai Electric Power Co. Kennedy said the system could be used by any existing or new coal power plant The equipment Hovorka and her team use to track carbon at the oil field employs off-the-shelf technology for the same reason.

The goal is to work out any kinks in the monitoring protocol, so it can be used by other companies, a goal she believes is well within reach.

“It’s not super hi-tech, wizbang. It’s regular old equipment and a clever inversion,” she said. “Get it cheap, get it practical, and get it ready to hand off. This is a tremendous opportunity.”

Ultimately, Tinker said Petra Nova can act as a model for others interested in reducing CO2 emissions from coalfired power plants.

“The combination of carbon capture and sequestration from a coal plant, enhanced oil recovery to provide additional energy and offset costs, and monitoring and verification of the CO2, is an important step along the path towards capturing and storing CO2 at a much larger scale,” he said

Back to the Newsletter