Alternative Carbon Carrier Technology Could Improve Oil Production — and Carbon Storage Too

August 14, 2025

A new method for enhanced oil recovery proposed by researchers at The University of Texas at Austin is showing promising results in modeling studies — producing more oil, storing more carbon, and doing so more safely than conventional enhanced oil recovery methods.

This trifecta of benefits stems from alternative carbon carrier technology research being led at UT.

Alternative carbon carriers are chemical compounds specifically engineered to store larger quantities of carbon molecules in subsurface formations. When these compounds are synthesized from carbon dioxide (CO2), it can help optimize the transportation, utilization, and storage of this greenhouse gas.

In a study that applied the technology to enhanced oil recovery scenarios, researchers at the UT Jackson School of Geosciences and the Cockrell School of Engineering found that the new carbon carrier method recovered up to 19.5% more oil and stored up to 17.5% more carbon than conventional enhanced oil recovery methods.

“The idea behind this technique is to maximize oil recovery while also increasing the amount and security of carbon storage,” said the study’s lead author Abouzar Mirzaei-Paiaman, a research assistant professor at the Jackson School’s Bureau of Economic Geology.

The results were published in Energy & Fuels, a journal of the American Chemical Society.

Oil and gas companies have been using enhanced oil recovery (EOR) to squeeze more oil out of reservoirs for decades. CO2-based EOR works by using CO2 gas to dislodge the residual oil from pores in the rock, and traps the CO2 underground in the process.

With carbon capture and storage technology, it’s possible for companies to use CO2 emissions produced by burning hydrocarbons to recover more oil — which helps reduce the net carbon footprint of the oil by keeping some of the emissions out of the atmosphere. However, when it comes to maximizing the amount of carbon emissions stored in a reservoir space, it’s better to treat CO2 as a starting point for synthesizing more effective carbon carriers, said study co-author Ryosuke Okuno, a professor in the Cockrell School’s Hildebrand Department of Petroleum and Geosystems Engineering.

“We don’t really have to use the CO2; we can find a better way,” he said. “Our idea was to capture the CO2 and to convert the CO2 into a formate species like sodium formate or potassium formate.”

Formate is a carbon-based molecule that can be synthesized from CO2 gas. It’s more readily stored in the rock pores than a comparable quantity of CO2 gas in the same conditions, according to Okuno.

Moreover, water-based solutions of formate compounds are also more viscous than CO2, which helps improve efficiency in recovering remaining oil and storing carbon in the formation.

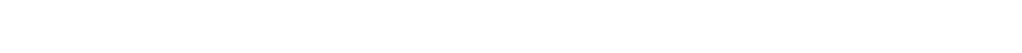

The EOR method tested by the researchers involved alternating slugs of CO2 gas to dislodge the oil with slugs of the water-based formate solution to help sweep the oil toward a production well. The researchers tested their method against two conventional EOR methods: One using CO2 gas alone, the other alternating slugs of CO2 gas and water.

All three EOR methods were tested in a simulated reservoir that was created using data from real oil fields in the Permian Basin, in West Texas.

The researchers found that the new carbon carrier method increased oil recovery by 19.5% compared to exclusive CO2 injection and by 1.9% compared to combined CO2 and water injection. For carbon storage, the carbon carrier method increased carbon storage by 2.5% compared to exclusive CO2 injection and 17.9% compared to combined CO2 and water injection.

In addition to oil recovery and carbon storage, the researchers also analyzed how securely the carbon was stored in the reservoir. They found that the formate-alternating-CO2 injection was the most secure option because it minimized the amounts of free-flowing CO2 — which can potentially escape from the reservoir. It also created a chemically buffered environment that could better preserve the integrity of the reservoir rock.

Across the board, the study shows promising results for EOR with carbon carriers. However, making it a reality for industry to refine and develop further will require more steps, said Okuno. For one, formate is not yet being produced from CO2 at the quantities needed to sustain EOR production.

Mirzaei-Paiaman has studied potential financial carbon storage incentives for carbon carrier technologies. He said that aligning policy so that it maximizes carbon storage benefits could help spark a market for carbon carriers.

“Whenever policy and regulations support a technology, companies move toward that direction,” he said.

The research was funded by the State of Texas Advanced Resource Recovery (STARR) program, a research program at the Bureau of Economic Geology focused on maximizing the production and profitability of earth resources in Texas while encouraging responsible economic development, supporting education and environmental stewardship. The Energi Simulation Industrial Affiliate Program on Carbon Utilization and Storage in the Center for Subsurface Energy and the Environment also supported the research.

For more information, contact: Anton Caputo, Jackson School of Geosciences, 210-602-2085; Monica Kortsha, Jackson School of Geosciences, 512-471-2241; Julia Sames, Department of Earth and Planetary Sciences, 210-415-9556.