Laser Mode ICP-MS

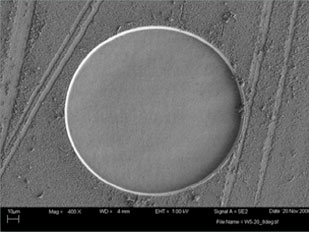

Excimer laser ablation pit (courtesy of NewWave)

Laser Ablation ICP-MS Capabilities

- Laser Ablation ICP-MS (LA-ICP-MS) can be considered the trace element microprobe

- In-situ trace elements directly from solid

- Rapid, multi-element with sub-ppm detection

- Minimal or no sample preparation required

- Spatial relationship or phase association characterized at high spatial resolution

- Qualitative to fully quantitative

- Capable of < 5% RSD precision

Method Overview

LA-ICP-MS is a useful analytical technique to derive spatial compositional information from solid sample surfaces. Spots or line scans are typically analyzed. The laser essentially acts as a high precision photon “jackhammer”, which generates a particulate aerosol that is carried to the torch and sample introduction system of the ICP-MS. Laser ablation energy is concentrated at a set focal distance, thus samples appropriate for LA-ICP-MS should present a flat uniform surface. Thin sections and polished slabs work very well and the laser cells are designed to accommodate such samples. The standard laser cell can accommodate a ~6 cm diameter sphere; although spherical samples are NOT encouraged. Laser control parameters for optimal aerosol generation can vary appreciably depending on the sample material.

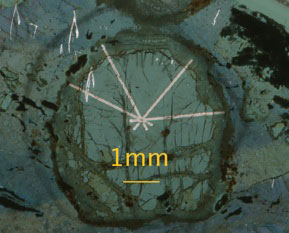

Four separate core-to-rim line traverses (20µm spot) in a partially resorbed garnet.

Trace Element Determinations

One of the challenges for LA-ICP-MS is calibration. Given a constant laser source, the ablation efficiency (laser coupling) can vary markedly among different materials. To compensate for this variation, the intensity ratio of an analyte to an internal standard in a sample can be normalized to that for a standard of known composition. For silicate materials (rocks, glasses, ceramics), synthetic reference materials (typically glasses like NIST 612, 610) are often used for normalization; there are also carbonate and sulfide reference standards. Accordingly trace element determinations involve analyses of both standards and unknowns.

Laser Ablation Projects

- The ICP-MS is tuned in solution mode, switched over from solution to laser ablation as the sample introduction mode, then retuned while ablating a reference standard.

- Projects typically require some method development from representative sample material from this point. The objective is to optimize ablation parameters on representative samples and obtain a robust and stable signal on the detector of the ICP-MS. Small spot sizes and lower laser repetition rates will have lower intensities, but faster wash out times. Overly energetic ablation may produce a range of particulate sizes that result in a broadened washout tail. The laser may defocus during analysis if the sample ablates too quickly relative to the spot dwell time or scan rate. For spot analyses the objective is to generate, maintain, and measure stable ion intensities over a time interval sufficient to generate robust counting statistics. Similarly for line scan analyses the objective is for a moving spot to consistently ablate the sample surface and deliver a representative particulate flux to the ICP-MS. Laser energies for spots are generally lower than for line scans.

- Once basic method and laser parameters are set, analyses can begin. Typically one or more reference materials are analyzed in replicate before measurements of unknowns, then reanalyzed periodically throughout the analytical session to monitor analytical drift. Calculations of trace element concentrations require determination of: (1) net intensities, thus analyte background baseline intensities (laser off) must be subtracted from analyte intensities with the laser on, (2) knowledge of an internal standard concentration for unknown samples (by assumed stoichiometry, EPMA analyses, or other), and (3) knowledge of the reference standard composition for the full suite of analyte isotopes. Analytical time to complete projects depends on number of samples, sample types, and time required to establish x-y-z ablation targets.

- From this point the user can (1) stop the charge clock and process their own data based on routine LA-ICP-MS chemometrics, or (2) elect to have their data processed for them offline. The output for the latter option is a spreadsheet with concentrations as appropriate for spot or line scan analyses. Data processing is often the most time-consuming aspect of a LA-ICP-MS project. Files can be numerous and large (many 10s of 1000s of rows), particularly for high-resolution line scans. Processing involves screening of outliers, net intensity calculation, and conversion to concentrations based on internal standard normalization from reference materials.

Please contact the lab for further information about laser ablation projects.

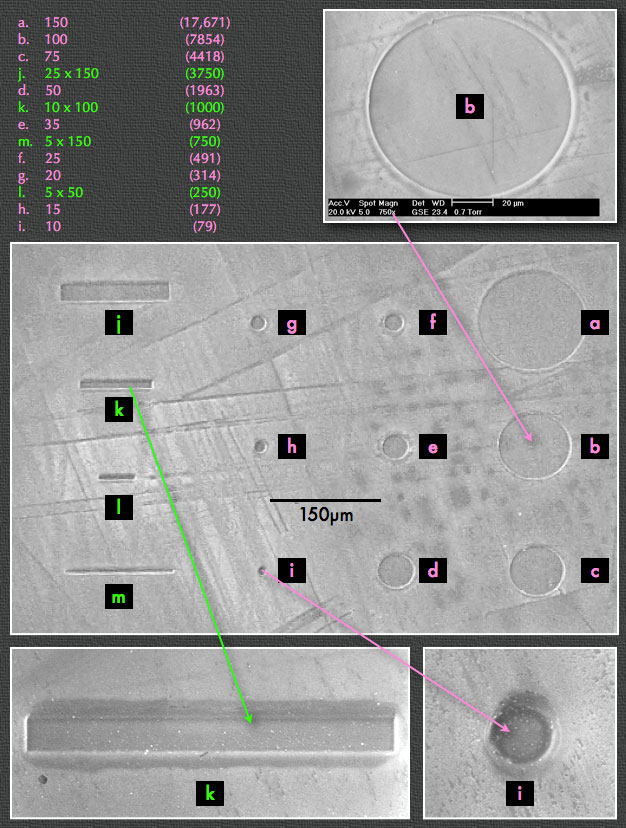

New & Cool – New Slit Laser Ablation Apertures

Rectangular spot options (slits) were added to the UP 193-FX laser system in May, 2010. The slit options (j-m shown below) are ideal for performing high-resolution trace element transects across zoned minerals or cement bands while minimizing aliasing in the temporal growth domain. Slit dimensions range between 50 and 150µm in length and 5 to 25µm in width.

Table of spot diameters, slit dimensions and (cross-sectional areas). All units in µm or µm^2.

Close-up view of the 10 x 100µm slit and 10µm spot. This slit has a cross-sectional area nearly 13 times larger than the 10µm spot, slightly larger than that for a 35µm spot (see table above). Scanning with the slit aperture parallel to mineral phase growth bands thus benefits from much larger analyte intensities without sacrificing temporal/spacial resolution.