Mineral Physics Lab

The Mineral Physics Group at The University of Texas at Austin mainly uses diamond anvil cells to study material properties in high pressure-temperature conditions. The DACs are integrated with laser and synchrotron X-ray spectroscopic techniques to probe properties of materials under extreme high pressure-temperature conditions. People with interest in collaboration are welcome to contact Dr. Lin for details about our research facilities. We use the following techniques for our research:

–Optical Raman and IR spectroscopy: lattice vibration, phase identification, phase transition

–Ruby fluorescence system: pressure measurement

–Laser heating and external heating: generation of high-temperature conditions

–Brillouin Light Scattering: elastic constants and elasticity

–Impulsive Stimulated Light Scattering and ps-Thermal Reflectance (ps-TTR): elasticity and thermal conductivity

–X-ray diffraction: crystal structure, phase transition, thermal equation of state

–High-energy X-ray diffraction: paired-correlation function for liquids/glasses

–Designer diamond anvil cell: electrical conductivity, metallization

–X-ray emission spectroscopy and RXES: electronic spin state/transition

–Mossbauer spectroscopy: spin and valence states of iron

–Nuclear Resonant Inelastic X-ray Scattering Spectroscopy: phonon density of states, vibrational/elastic/thermodynamic properties, sound velocities

–X-ray Raman spectroscopy: electronic structure, electronic transition

–High-energy resolution inelastic X-ray scattering: lattice dynamics, sound velocities

–Piston-cylinder apparatus: to synthesize high-quality samples

–Electrical probe: electrical conductivity

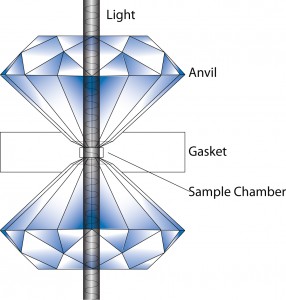

1. Diamond Anvil Cells:

The Mineral Physics Group commonly uses a variety of diamond anvil cells to generate pressures as high as 2-3 Mbars. The diamond anvil cell technique takes the advantage of the specific properties of diamond: diamond is the hardest known materials, very inert to chemical reaction, and transparent a wide rage of electromagnetic waves. These properties enable us to carry out in situoptical and synchrotron X-ray spectroscopic measurements at extreme pressure-temperature conditions. The DACs we have include symmetric, short symmetric, 2-fold and 3-fold, hydrothermal (Bassett type), symmetric EHDAC, and modified wide-opening. Since our machine shop can machine high-precision DACs for us, we can design and tailor DACs for specific experiments.

In a recent study, Dr. Lin and co-workers have generated pressures up to 250 GPa and temperatures up to 3000 K which are more relevant to core Earth’s conditions.

2. Custom-Built Optical Raman System and Renishaw inVia micro-Raman (5/2016):

The Renishaw system has a number of functions with 1200 and 2400 gratings:

— 532 nm laser with Eclipse filter with lowest wavenumber at ~10 cm-1;

— 532 nm laser with edge filter (cut-on) with lowest wavenumber at ~50 cm-1;

— 473 nm laser with polarizer/analyzer (polarized Raman setup) with lowest wavenumber at ~150 cm-1;

The custom-built Raman system was designed and built by Dr. Lin. The system’s main parts consist of Verdi V2 532-nm laser, Andor iCCD, and OptiGrate filters. The system allows ultralow wavenumber measurements down to approximately 10 cm-1. Learn more about “Raman Spectroscopy and the Diamond Anvil Cell”

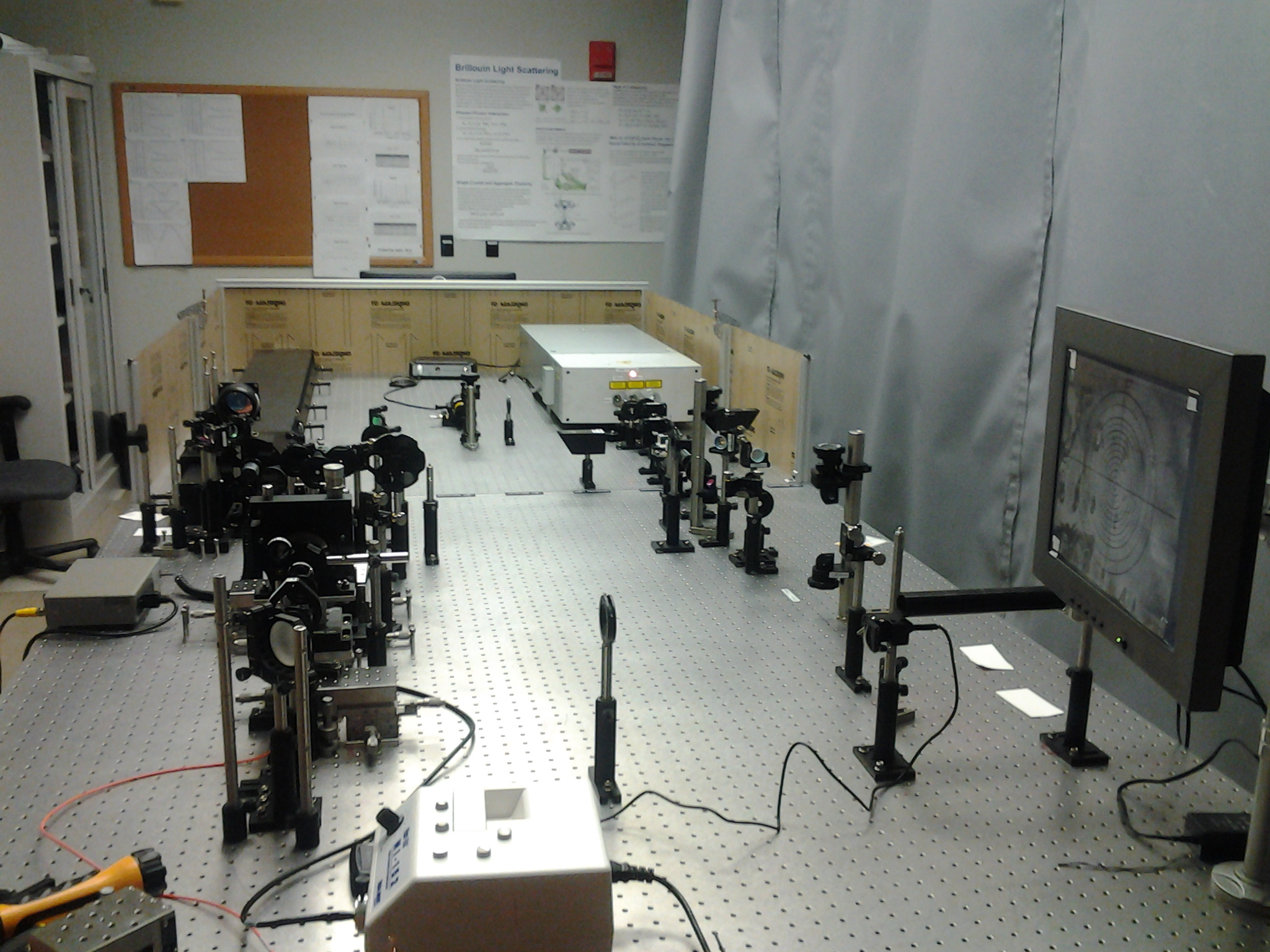

3. Brillouin Light Scattering System:

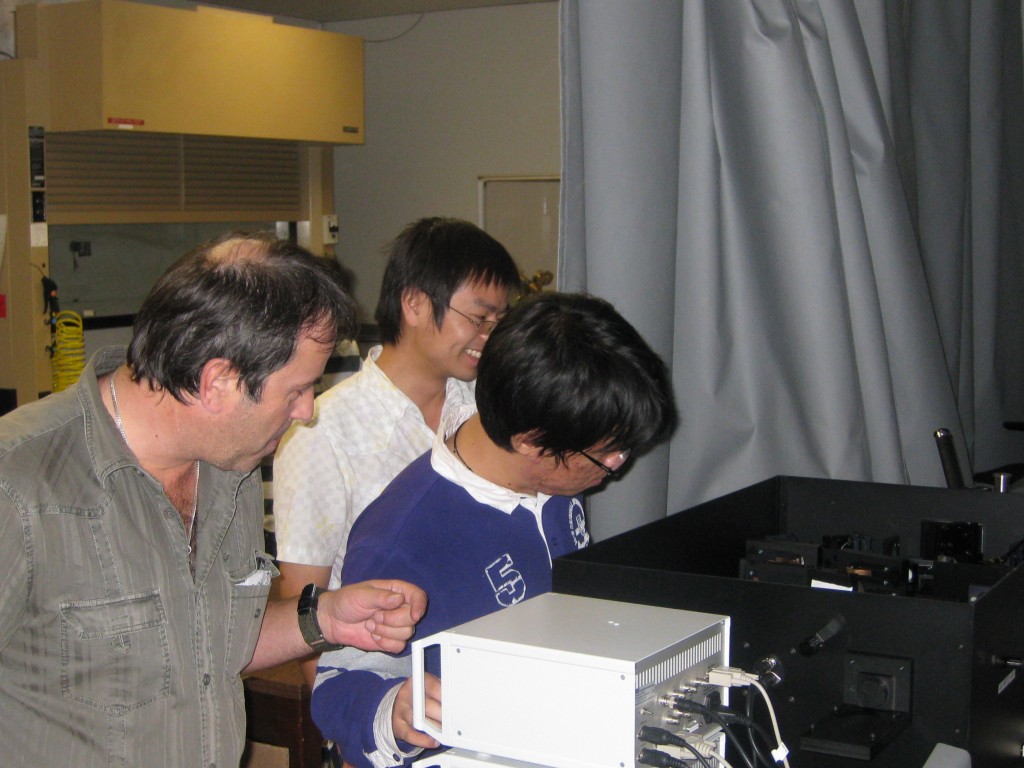

The system is equipped with a JRS Interferometer, a Coherent Verdi V2 532-nm laser, and PMT/APD detector for measuring elasticity in a high-pressure diamond anvil cell. The Laser Component’s APD detector (Count-10B) is a new addition that has 70% QE. This system was funded by CDAC and JSG matching programs.

JRS technician (left), Mr. Erwin Eisenegger, showing graduate students how to operate the interferometer.

4. AIR Loader:

The gas loading system was built by Dr. Afu, Dr. Iota, and Mr. Roger Gary (AIR). The system’s main parts consist of a Newport Scientific super-pressure compressor and a High-Pressure Equipment clover-leaf pressure vessel. The system is designed to load various gases such as Ar, Ne, He, CO2, and CH4 up to 30,000 psi into a DAC. It is interesting to mention the following story about building the system: the compressor (built in 1960s) was a donation from Mechanical Engineering. With the free compressor, the system was built with a very minimum cost of 30-35 K total, with safe operation and easy maintenance.

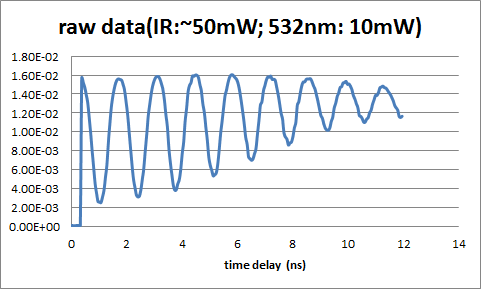

5. Impulsive Stimulated Light Spectroscopy:

The system is equipped with a Coherent Talisker 532/1064 nm laser (8 watts max.), Aerotech linear stage (5 ft long), and National Instruments’ Lab View interface. The system is now in routine operatiion for measuring acoustic velocities of samples in extreme environments in a DAC. Our next step is to implement the thermal diffusivity measuring capability by adding a phase mask, an APD detector, and a continuous green laser (from the nearby BLS system). Our ultimate goal for the system is to couple it with laser and/or extrenal heating for sound velocity and thermal diffusivity study at relevant conditions of the Earth’s interior as well as planetary bodies (eg., icy planets and satellites)–hopefully, this will happen in 1-3 years.

6. Infrared Laser Heating System:

The system is equipped with an infrared laser that is split into two beams to heat samples in diamond anvil cells to high temperatures (thousands of K). The system can be used for material synthesis and can also be combined with other techniques such as electrical conductivity to investigate material properties at high pressure and temperature.

7. Sample Preparation Lab:

- Minitool micro-mechanical drilling system

- Hylozoic Products’ Electrical Discharge Machining (EDM) system

- High-resolution Leica stereomicroscope with a high-resolution Leica camera

- Olympus microscope

- Ultrasonics, heating stage, Mitutoyo micrometers

8. Piston-Cylinder Apparatus:

The QUICKpress non-end loaded piston cylinder apparatus, produced by Depths of the Earth allows pressures and temperatures in the range of 0.3GPa to 4.0GPa and 25°C to 2000°C to be routinely achieved. The system was built by NSF Instrumentation and Facility grant to Dr. Gardner and Dr. Lin.

9. Synchrotron Radiation Centers:

(Dr. Lin’s group uses these facilities on a regular basis):

Advanced Photon Source, Argonne National Laboratory

GeoSoilsEnvironsCollaborative Access Team (GSECARS) Sector 13

Sample preparation labs (stereomicroscope, optical Raman, EDM and mechanical drilling systems, high-pressure gas-loading system)

Radial and axial X-ray diffraction with laser-heated diamond cells

X-ray emission spectroscopy with a laser heating system

Resonant X-ray emission spectroscopy

XOR Sector 3

Synchrotron Mössbauer spectroscopy with a laser heating syste

Nuclear resonant inelastic X-ray scattering with a laser heating system

High-resolution inelastic X-ray scattering

High-Pressure CAT

Synchrotron Mössbauer spectroscopy with external-heating capability

X-ray Raman

X-ray emission spectroscopy and Resonant X-ray emission spectroscopy

Radial and axial X-ray diffraction beamline with laser-heated diamond cells (CCD and an image plate detectors)

Sample preparation labs (stereomicroscope, optical Raman, EDM and mechanical drilling systems)

SPring-8, Japan

BL12XU beamline

X-ray emission spectroscopy

Resonant X-ray emission spectroscopy

X-ray Raman

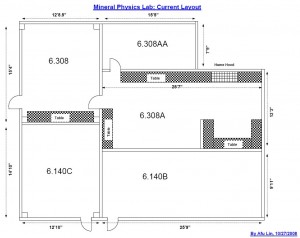

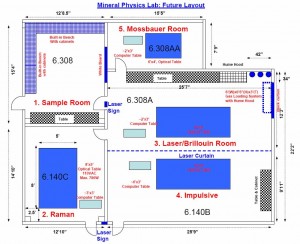

10. The Behind-The-Scene Story:

The story started when Dr. Lin moved to UT Austin in the summer of 2008 to become a faculty in the Department of the Geological Sciences:

(1). This was how it all got started in July 2008:

(2). Delivery of the optical tables:

Two Smart tables from Newport Co. were purchased and delivered in early April 2009. The 12″x5″ table was assembled from two pieces of 6″x5″ tables as the building elevator was too small to handle it.