Proposal

Executive Summary

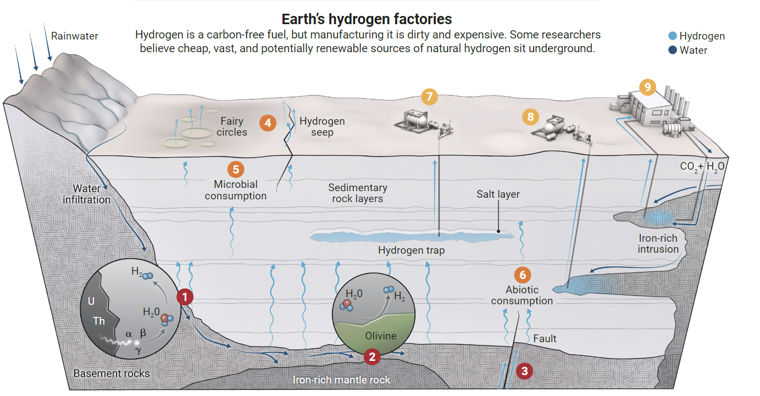

This project investigates the effect of pH on orange hydrogen production through the process of serpentinization, where mafic and ultramafic minerals, such as olivine, react with water to form serpentinite. The study specifically examines the impact of pH on hydrogen production rates by conducting experiments at two different pH values (pH 11 and pH 7) under conditions of atmospheric pressure and elevated temperature (200°C).

Using inductively coupled plasma mass spectrometry (ICP-MS), the elemental composition of the products was analyzed, focusing on the concentrations of key elements including sodium (Na), magnesium (Mg), iron (Fe), calcium (Ca), nickel (Ni), and chromium (Cr), which are critical to understanding the serpentinization reaction and its efficiency in hydrogen generation.

It is hypothesized that increasing the pH will enhance the dissolution rate of minerals, leading to a higher concentration of dissolved elements and, consequently, a greater volume of hydrogen gas produced. The results of this study aim to provide insights into optimizing conditions for more efficient hydrogen production, with implications for sustainable energy solutions. By testing the effects of pH and temperature, this research contributes to the broader understanding of the serpentinization process and its potential for hydrogen production.

Objectives

To investigate the effect of pH on hydrogen production rates during serpentinization of olivine and other mafic minerals, by analyzing the dissolution of key elements (Na, Mg, Fe, Ca, Ni, Cr) under controlled temperature and pressure conditions.

Methods

Olivine grains, approximately 100 microns in diameter, were first cleaned using a sonicator to remove surface contaminants. After cleaning, the grains were dried in an oven at 60°C for several hours to ensure complete moisture removal. Following the drying process, four samples of 0.75 grams of olivine were put in four vessels with each vessel containing 20 mL of fluid. For the pH 11 condition, a stock solution of pH 11 was prepared, while for the pH 7 condition, deionized (DI) water was used. The experiments were performed in duplicates, with each set of conditions (pH 7 and pH 11) being replicated to ensure the reliability of the results. The reactions were conducted at 200°C for 16 hours under atmospheric pressure. After the reaction period, the solid residue was separated from the aqueous phase by filtration, and samples of the filtrates from both pH 7 and pH 11 conditions were collected and preserved for subsequent analysis.

The elemental composition of the dissolution products was analyzed using inductively coupled plasma mass spectrometry (ICP-MS). The filtered solutions were appropriately diluted and spiked with an internal standard (Sc and Ge) to correct for matrix effects. The concentrations of sodium (Na), magnesium (Mg), iron (Fe), calcium (Ca), nickel (Ni), and chromium (Cr) were determined by monitoring their respective isotopes. ICP-MS was performed in collision mode with no gas mode and helium (He) as the collision gas to minimize polyatomic interferences from Ar-based ions. Calibration was carried out with matrix-matched standards to account for matrix effects arising from varying concentrations of dissolved elements in the pH 7 and pH 11 solutions.

Analytes:

In the context of orange hydrogen production, key analytes should be examined using ICP-MS to ensure process efficiency, product purity, and compliance with environmental regulations. The specific analytes depend on the materials used (water, catalysts) and the potential contaminants introduced during the production process.

Key Analytes to Monitor:

Transition Metals: Iron (Fe) and Zinc (Zn) may enter the system through feedstocks, corrosion of equipment, or catalyst wear. Iron is essential in hydrogen production. Zinc needs to be monitored to ensure they do not contaminate the hydrogen or affect efficiency. Nickel (Ni) and Chromium (Cr) are common in catalysts used in electrolysis and other hydrogen production methods. Monitoring their presence ensures the catalyst’s performance and helps track degradation over time. They may also be contained in olivine as trace elements.

Alkali and Alkaline Earth Metals: Sodium (Na) and Potassium (K): Present in water sources or electrolytes, these metals may impact the efficiency of electrolysis if they accumulate. Magnesium (Mg): Often found in water, these elements can lead to scaling or fouling in electrolytic cells, reducing efficiency and requiring frequent maintenance. It is also a major element in olivines, so its concentration can reflect dissolution rate.

Interference Management

Interference management is crucial in ensuring accurate measurement and optimal performance during the production of hydrogen using ICP-MS.

- Transition Metals:

Transition metals such as Nickel (Ni) are often used in catalysts. Their presence can interfere with each other’s detection due to isobaric overlaps and polyatomic interferences. To overcome that problem we add internal standards like Germanium (Ge) and Scandium (Sc) using the peripump to the samples to help correct for signal fluctuations and matrix effects. We also used collision/reaction cell (CRC) with He mode to remove polyatomic interferences like the interference from ArO+ on Fe analysis. Moreover, standards and samples wee prepared in similar matrices to reduce matrix effects and improve accuracy. - Alkali and Alkaline Earth Metals:

Challenges: Elements like Sodium (Na), Potassium (K), and Magnesium (Mg) are present in high concentrations in natural waters and can cause matrix suppression effects, leading to signal suppression or enhancement. So, dilution was made to decrease their concentration. We also calibrated with stocks containing these elements, ensuring that the sample and standard have similar matrix compositions, minimizing matrix effects.

Expected Outcomes

We expect more iron and magnesium concentrations with the higher (pH=11) solution than by using DI water (pH=7). That is because dissolution is faster at these high pH’s.

Moreover, we expect a high rise in iron concentration with time. Iron dissolution means more hydrogen production. This is a slow process and it typically needs time. That’s why we expect a sharp increase after some time.

Budget

The samples for this study will all be in liquid form, and as a result, will be analyzed using solution mode ICP-MS. I anticipate analyzing approximately 18 samples, with a unit cost of $20 per sample, resulting in a total cost of $360.